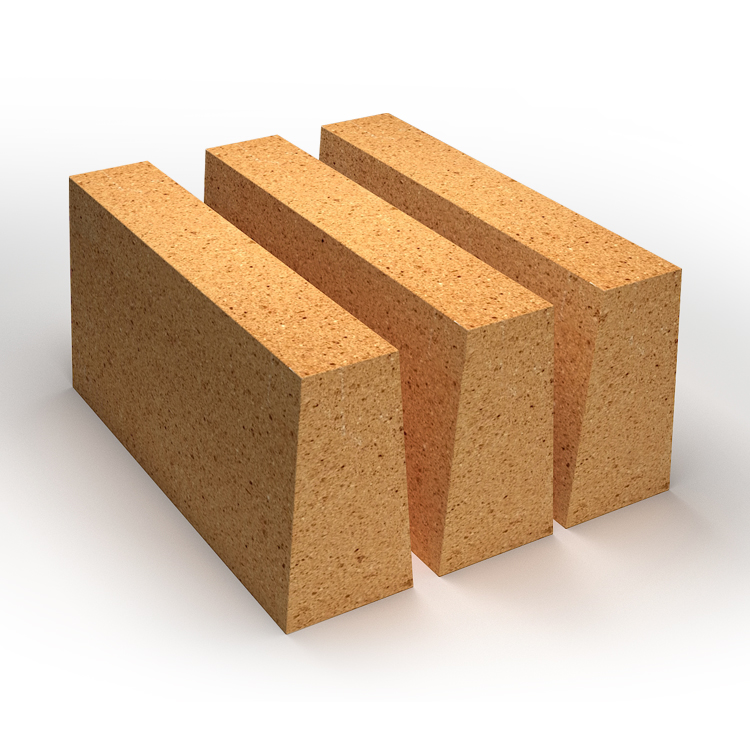

Brick na-eguzogide okpomọkụ dị elu maka Kilns, oven

Dị ka akụkụ dị iche iche nke brik refractory si dị, ha nwere ike kewaa n'ime ụzọ ise, ya bụ: brik silicon-alumina series, brik ndị na-eme ka ihe ndị na-emepụta ihe na-emepụta ihe, brik ndị nwere carbon, brik ndị nwere zirconium, na brik ndị na-ekpo ọkụ na-ekpo ọkụ.

Ọ bụghị naanị otu ụdị brik na-atụgharị ọkụ na-ewu ọkụ ọ bụla, ọ chọrọ nchikota brik dị iche iche.

(1) brik silica na-ezo aka na brik ndị na-emegharị emegharị nwere ihe karịrị 93% SiO2, nke bụ isi ụdị brik na-emegharị acid.A na-ejikarị ya eme oven coke masonry, kamakwa maka oghere na akụkụ ndị ọzọ na-ebu ibu nke ọkụ ọkụ nke iko dị iche iche, seramiiki, carbon calciners, na brik na-atụgharị.A na-eji ya na akụrụngwa okpomọkụ dị n'okpuru 600 Celsius C yana nnukwu mgbanwe okpomọkụ.

(2) brik ụrọ.Ihe mejupụtara brik ụrọ na-abụkarị nke mullite (25% ruo 50%), oge iko (25% ruo 60%), na cristobalite na quartz (ruo 30%).Ọtụtụ mgbe, a na-eji ụrọ siri ike mee ihe dị ka ihe eji eme ihe, a na-emepụta clinker tupu oge eruo wee gwakọta ya na ụrọ dị nro.Enwere ike ịgbakwunye obere iko mmiri, ciment na ihe ndị ọzọ iji mee ngwaahịa na-adịghị ọkụ na ihe ndị na-enweghị ụdị.Ọ bụ brik a na-ejikarị eme ihe n'ọkụ ọkụ, stovu na-ekpo ọkụ ọkụ, ọkụ ọkụ, ọkụ ọkụ, ọkụ lime, rotary kiln, ceramics, na brik na-agbapụ ọkụ.

(3) brik na-ekpu alumina dị elu.Ngwakọta ịnweta nke brik na-ekpu alumina dị elu bụ corundum, mullite, na akụkụ iko.Akụrụngwa ndị ahụ bụ nnukwu alumina bauxite na sillimanite eke eke, na e nwekwara fused corundum, sintered alumina, sịntetik mullite, na clinker calcined na alumina na ụrọ n'ụzọ dị iche iche.A na-emepụta ya nke ukwuu site na usoro sintering.Mana ngwaahịa ndị a na-agụnyekwa brik nke a na-agwakọta agwakọta, brik ndị a kpụrụ akpụ, brik na-adịghị ọkụ, na brik ndị na-enweghị ụdị.A na-eji brik dị elu alumina refractory eme ihe n'ọtụtụ ebe na ụlọ ọrụ igwe na igwe, ụlọ ọrụ igwe anaghị agba nchara, na ụlọ ọrụ ndị ọzọ.(4) Brick corundum refractory, brik corundum na-ezo aka n'ụdị brik na-atụgharị na ọdịnaya AL2O3 nke na-erughị 90% na corundum dị ka isi usoro, nke nwere ike kewaa brik corundum siri ike na brik corundum jikọtara (5) High- alumina na-ekpuchi ọkụ na-ekpuchi brik na-atụgharị ọkụ.Ọ bụ brik na-ekpuchi ọkụ na bauxite dị ka isi ọdịnaya AL2O3 nke na-erughị 48%.Usoro mmepụta na-anabata usoro ụfụfụ, a pụkwara iji usoro mgbakwunye ọkụ ọkụ.Enwere ike iji brik na-etugharị ọkụ dị elu-alumina na-ekpuchi ọkụ ọkụ iji wuo ihe mkpuchi na-ekpo ọkụ na ebe a na-enweghị ike ikpo ọkụ na-ekpo ọkụ na-ekpo ọkụ.Mgbe na kọntaktị kpọmkwem na ire ọkụ, n'elu kọntaktị okpomọkụ nke izugbe elu-alumina okpomọkụ mkpuchi refractory brik agaghị elu karịa 1350 ℃.Mullite na-ekpuchi ọkụ na-ekpuchi brik nwere ike ịkpọtụrụ ọkụ ozugbo ma nwee njirimara nke nguzogide okpomọkụ dị elu, ike dị elu, na mmetụta dị ịrịba ama na-azọpụta ike.Ọ dabara adaba maka mkpuchi nke ọkụ pyrolysis, ọkụ na-ekpo ọkụ na-ekpo ọkụ, kiln rola seramiiki, kichin poselin eletriki, na ọkụ ọkụ dị iche iche.(6) Urọ na-ekpuchi ọkụ na-ekpuchi brik dị arọ bụ brik na-ekpo ọkụ na-ekpo ọkụ nke nwere ọdịnaya AL2O3 nke 30% ruo 48% nke ụrọ na-eme ka ọ bụrụ isi ihe.Usoro mmepụta ya na-anabata ọkụ-apụ gbakwunyere usoro agwa na usoro ụfụfụ.Iji ụrọ refractory, beads na-ese n'elu mmiri, na clinker ụrọ na-atụgharị dị ka ihe eji eme ihe, na-agbakwunye ihe nkedo na sawdust, site na batching, ịgwakọta, ịkpụzi, ihicha, na ịgba egbe, a na-enweta ngwaahịa ahụ nwere nnukwu njupụta nke 0.3 ruo 1.5g/cm3.Ihe mmepụta nke brik na-ekpo ọkụ na-ekpo ọkụ na-eme ka ihe karịrị ọkara nke ngụkọta nke brik na-ekpuchi ọkụ.

A na-eji ya eme ihe n'ọkụ ọkụ, ọkụ ọkụ na-ekpo ọkụ, ọkụ ọkụ, ọkụ ígwè, oven coke, carbon oven, ladle, ladle casting systems, boilers, ciment kilns, glass kilns, tunnel kilns, rotary kilns, and shaft kilns na ndị ọzọ na-ekpo ọkụ ọkụ. na thermal akụrụngwa na-ọtụtụ ebe na-eji metallurgy, chemical ụlọ ọrụ, ceramics, coking, carbon, nkedo, ígwè, ọkụ eletrik, ihe ụlọ, mmanụ ala, na ndị ọzọ ọrụ.